Latest News

New Slitting Machine at the DYNOS Site in Troisdorf

Together with PSA Technology, a state-of-the-art slitting machine has been successfully commissioned at our Troisdorf site. The new system enables high-precision cutting of vulcanized fibre, tailored precisely to the individual requirements of our customers.

“With the new slitting machine, we are not only significantly increasing our productivity, but also relying on the latest control and safety technology,” explains Project Manager Mr. Brodesser.

“This ensures we are ideally positioned to meet the growing demands of our customers and respond even more flexibly to specific requests.”

This investment highlights our ongoing commitment to efficient, safe, and future-oriented production processes at the Troisdorf site – another step forward in providing our customers with the highest quality and maximum flexibility.

The Troisdorf location of the DYNOS Group expands its capacities

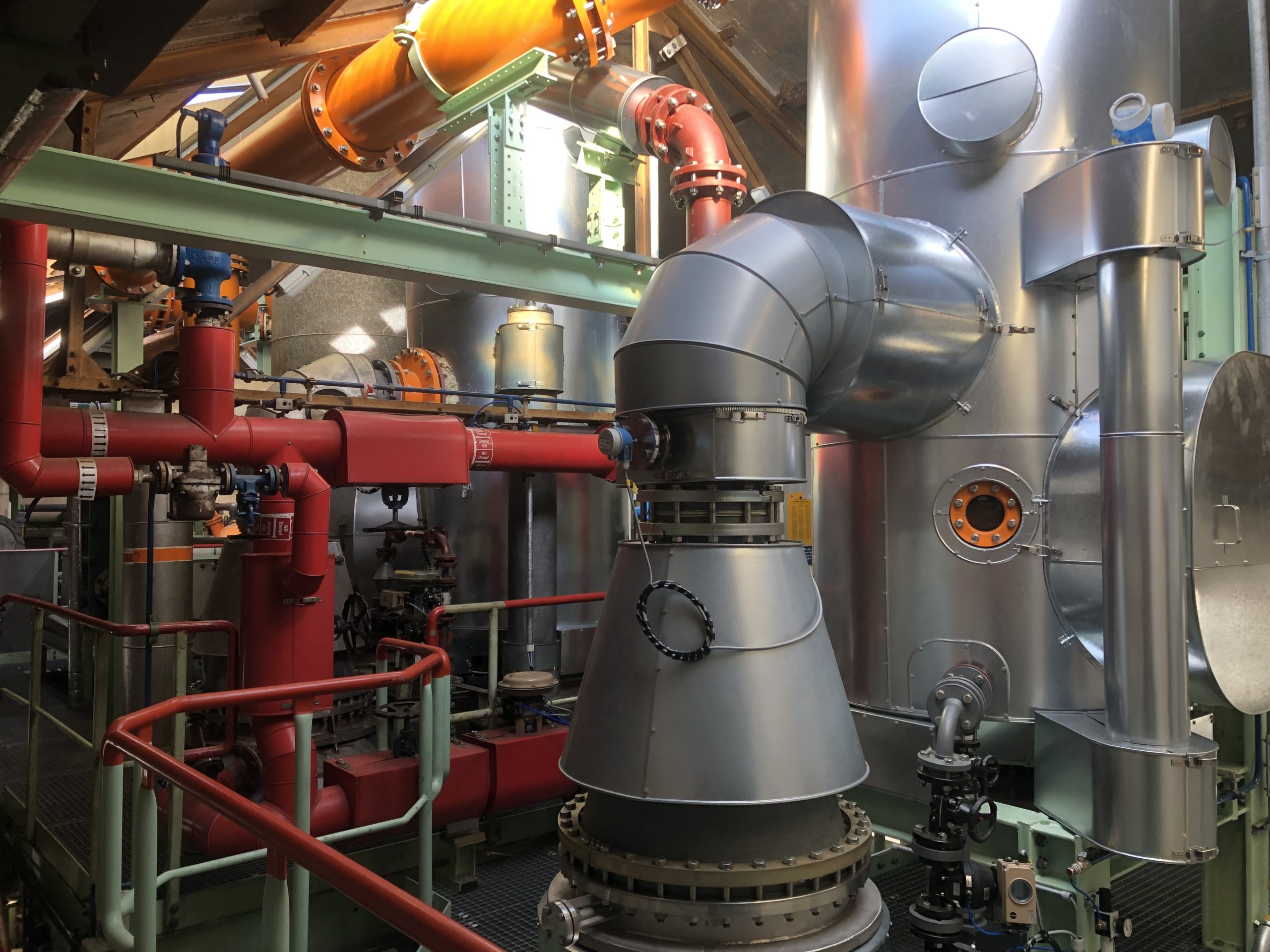

The capacity expansion of the vulcanised fibre plant in Troisdorf, near Bonn, was placed into operation on 2022 August, 22nd.

The third vaporization stage of the evaporation plant, designed and implemented by EBNER from Eiterfeld, Germany, ensures a significant increase in productivity for the overall output and thus enables an improved supply to our customers.

By using modern 3D planning technology, the tight space conditions could be optimally used and possible conflicts with other existing plant components avoided.

The state-of-the-art PCS (Process Control System) installed guarantees ideal usage and monitoring of the new plant, now by two PC screens instead of switchboards.

"A big kudos is owed to all those involved," said Project Manager of the Troisdorf location, Mr. Michael Skirke, "within the given short timeframe in cooperation with Ebner, the plant could be pre-installed during ongoing production, and put into operation during the planed summer shut-down. Thanks to the improved technology, the machine operators did not have any problems running in the plant.

Despite these challenging conditions, we were able to eliminate any risk of injury or accident, which is not a matter of course!"

"By expanding our capacity, we are taking a further step toward securing our market leadership. On behalf of the management board, I would like to expressly thank all those involved in the project. They have managed to adhere to the challenging schedule and the agreed budget." As quoted by Dr. Hans-Peter Koller, CEO and Owner of the DYNOS Group.

For a world with less plastic and

more natural materials

Natural fibre pulp and sustainable paper are increasingly in demand. In the course of the transformation towards sustainable processes and products, industry is intensively searching for alternative materials. DYNOS Pulp, DYNOS Vulcanized Fibre and other specialty papers, obtained from recycled materials, are playing an increasing role in this process; and this for very different applications: from abrasives to recycled yarns for the clothing industry to special solutions made from paper and vulcanized fibre. In laboratories around the world, further applications for pulp and paper are being sought as replacements for previous plastic solutions. We will keep you up to date.